Golden Batch For Milk Reception In The Dairy processing Industry.

Golden Batch for Milk Reception in the Dairy Processing Industry

Introduction

Achieving the “Golden Batch” in milk reception involves consistently receiving and processing raw milk batches that meet predefined optimal quality and composition standards. This use case explores how XMPro’s Intelligent Digital Twin Suite (iDTS) can be leveraged to optimize milk reception processes, ensuring each batch of raw milk received at a dairy processing plant aligns with these golden standards for quality, safety, and efficiency.

The Challenge

Managing raw milk reception in the dairy processing industry involves navigating several challenges: ensuring consistent quality amidst variability, efficiently scheduling and testing incoming milk, and adhering to strict safety standards. Successfully overcoming these hurdles is essential for maintaining product quality, operational efficiency, and regulatory compliance, underscoring the need for innovative solutions like the Golden Batch for Milk Reception.

Variability in Raw Milk Quality: Raw milk comes from various sources, leading to significant variability in quality, fat content, and microbial load.

Efficiency in Milk Reception: Managing the efficient reception, testing, and storage of raw milk while minimizing wait times and ensuring optimal use of reception capacity.

Compliance and Safety: Ensuring all received milk meets regulatory standards for safety and quality before processing.

Waste Reduction: Minimizing waste due to spoilage or rejection of milk that does not meet quality standards.

The Solution: XMPro’s Intelligent Golden Batch Solution for Milk Reception in the Dairy Industry.

XMPro’s Intelligent Digital Twin Suite (iDTS) is meticulously designed to address the unique challenges of milk reception in the dairy processing industry. By providing a cohesive and focused solution, it streamlines the process of managing raw milk quality and logistics, ensuring high standards of efficiency and quality assurance. Utilizing the sophisticated capabilities of XMPro iDTS, this approach transforms milk reception practices, guaranteeing consistent quality, operational excellence, and adherence to safety regulations.

Key Features

Advanced Sensor Data Integration & Transformation:

XMPro iDTS seamlessly incorporates real-time data from sensors tracking critical parameters such as temperature, flow rates, and quality indicators at milk reception points. This integration is vital for early identification of variations in raw milk quality and operational bottlenecks. It facilitates ongoing surveillance of milk reception processes, pinpointing potential discrepancies swiftly to prevent quality lapses or logistical inefficiencies.

Real-time Batch Monitoring and AI Quality Prediction:

The system provides detailed monitoring of milk batches, including information like batch number, volume received, and supplier data. Key quality indicators such as temperature, fat content, protein content, pH level, and somatic cell count are tracked against ideal values. AI-driven analytics predict the quality of the milk, offering suggestions such as blending higher fat% milk to meet quality targets.

Process Timeline and Tank Fill Level Visualization:

Users can track the progress of each step in the dairy processing timeline, from milk reception to aging, with real-time updates on tank fill levels, ensuring smooth transitions between production stages.

Energy and Efficiency Metrics:

The system offers insights into the plant’s operational efficiency with metrics like current energy efficiency, Overall Equipment Effectiveness (OEE), and Total Effective Equipment Performance (TEEP), allowing for informed decisions to optimize energy use and improve the yield.

Predictive Recommendations:

XMPro’s platform proactively provides recommendations to address potential issues in the process, such as culture viability concerns, firmness adjustments, and parameter optimizations for pasteurization. It also advises on final checks before commencement and during aging.

Interactive and Customizable Dashboards:

XMPro equips operators with interactive dashboards that display the current status of different batches, line status over the last 24 hours, and a current month’s downtime by cause. Recommendations for process improvements are also provided, enhancing decision-making and efficiency.

Discover XMPro’s Golden Batch Solution for Milk Reception in the Dairy Processing Industry

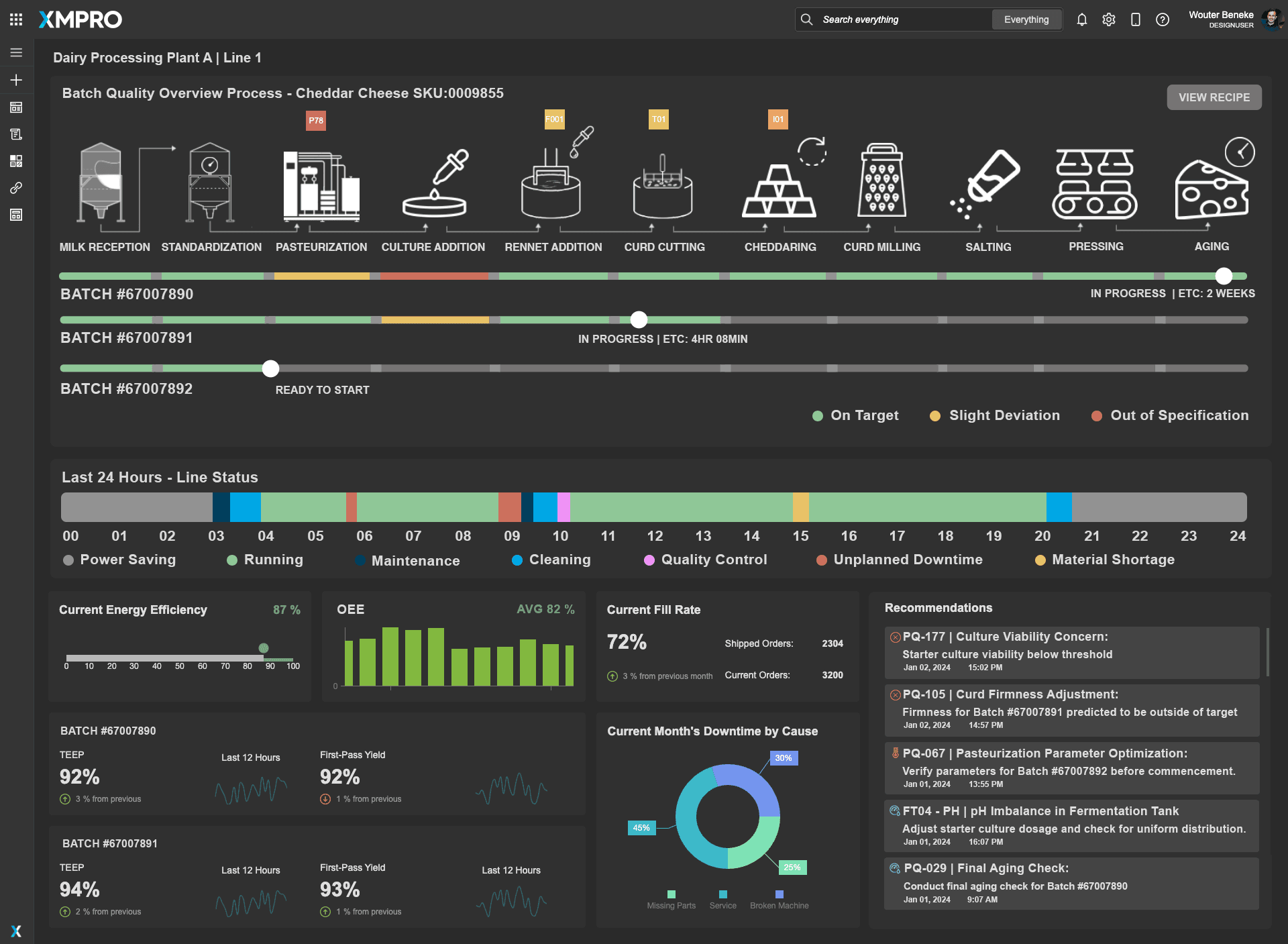

Figure1. Real-time Dairy Processing Plant Operations Dashboard

Comprehensive Dashboard for Dairy Plant Operations

This comprehensive operations dashboard is tailored for dairy plant managers and operators to oversee the cheese production process. It provides a complete view of the workflow from milk reception to cheese aging, displaying the current status of different batches and processing stages like standardization, pasteurization, and culture addition.

Batch Progress and Line Status:

The dashboard displays the progress of various cheese batches through their production stages, with detailed information on each batch’s status. Additionally, the ‘Last 24 Hours – Line Status’ section gives a color-coded timeline showing periods of running, maintenance, cleaning, quality control, and downtime.

Operational Efficiency Metrics:

Key performance indicators such as Overall Equipment Effectiveness (OEE) and energy efficiency are presented, alongside real-time updates on the fill rate of cheese production. The dashboard illustrates the plant’s operational efficiency, providing insights for potential improvements.

Predictive Recommendations:

XMPro’s system issues targeted recommendations to improve the cheese-making process, including alerts on culture viability concerns and adjustments for firmness and pasteurization parameters. It also suggests checks for pH balance in the fermentation tank and final aging checks, ensuring quality and consistency.

Granular Insights and Predictive Maintenance:

Detailed insights are available for each batch, with predictive analytics on equipment health and process efficiency. This includes monitoring Total Effective Equipment Performance (TEEP) and providing a breakdown of the current month’s downtime causes, helping to strategically plan maintenance and reduce potential interruptions.

Summary and Trend Analysis:

The dashboard offers a summary view of recent batch performance with trends in first-pass yield and a comprehensive look at operational data over time. It allows for quick assessments and informed decision-making to enhance production quality and efficiency.

User-Centric Interface:

With its user-friendly interface, the dashboard ensures that all information—from batch progress to efficiency metrics—is easily accessible, enabling efficient navigation and rapid retrieval of detailed data for strategic management.

This Dairy Processing Plant Operations Dashboard is an essential tool for monitoring and optimizing the cheese production line, enabling a proactive approach to quality control, maintenance, and operational excellence.”

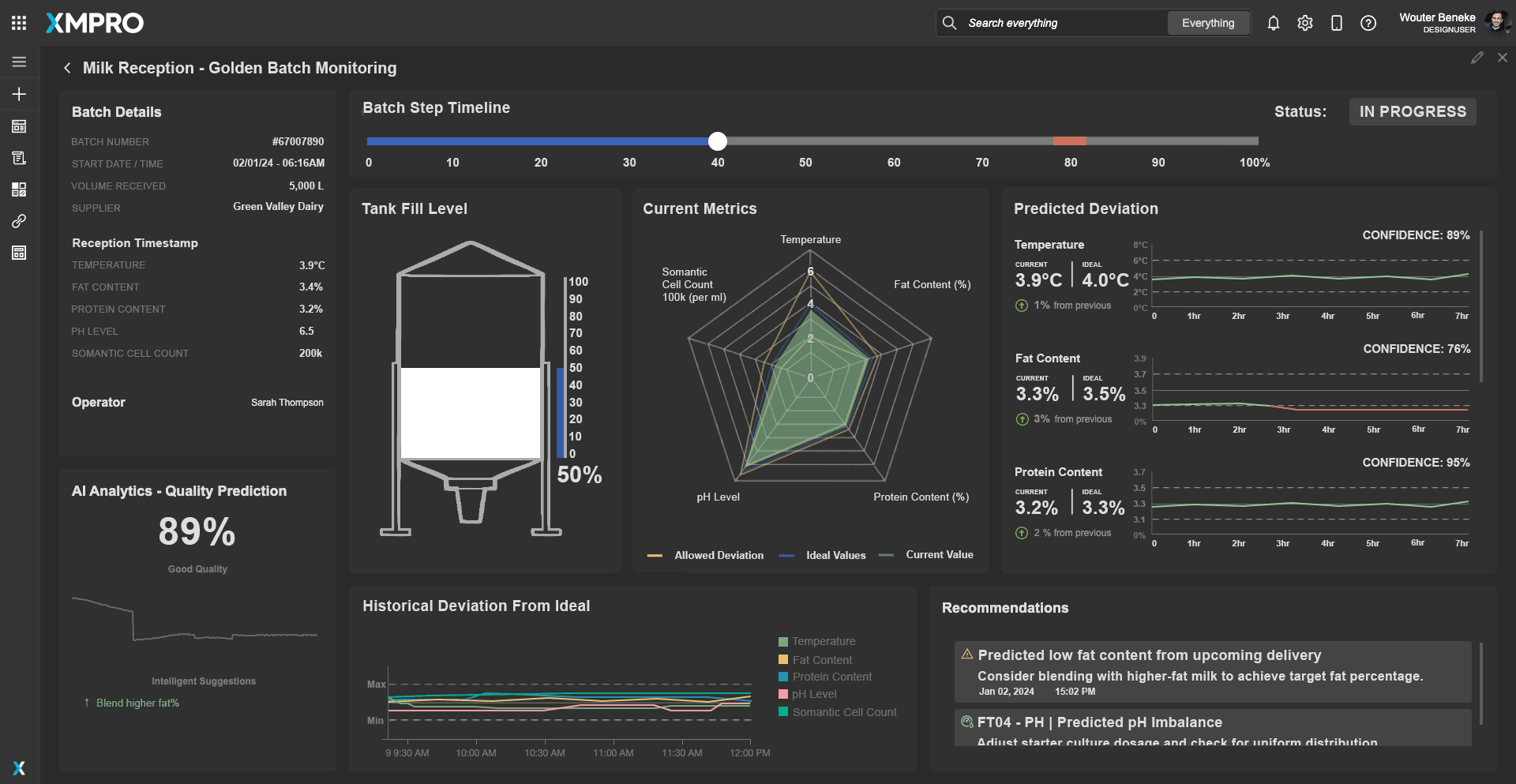

Figure 2. Drilldown View of Milk Reception Batch Monitoring Dashboard

The specialized Dashboard for Milk Reception Quality Monitoring is a pivotal component for managing the initial phase of dairy processing. It plays a significant role in assessing the quality of raw milk as it enters the facility, setting the stage for subsequent processing steps like pasteurization.

Comprehensive Milk Reception Monitoring:

XMPro’s Golden Batch Monitoring Dashboard is intricately designed to provide dairy processing professionals with a detailed view of milk reception operations. It showcases a thorough set of data for each milk batch, including batch number, start date/time, volume received, supplier, and reception timestamp along with key quality indicators like temperature, fat content, protein content, pH level, and somatic cell count.

Batch Progress and Tank Fill Level:

The dashboard features a Batch Step Timeline, clearly indicating the stage of the batch within the milk reception process. A visual representation of the tank fill level provides immediate information on the volume of milk currently being processed, ensuring resources are allocated efficiently.

Real-time Quality Metrics and AI Predictions:

Operators can view current quality metrics against ideal values through an intuitive radar chart, offering a real-time comparison of important factors such as somatic cell count and fat content. The AI Analytics section delivers a quality prediction score, in this case, showing 89% for good quality, along with intelligent suggestions like blending higher fat% milk to adjust quality levels.

Historical Data and Predictive Trends:

The dashboard presents a historical deviation from ideal chart, allowing users to track quality over time against allowed deviations. Predictive trend lines for temperature, fat content, and protein content offer foresight into potential deviations from ideal values, with a confidence level displayed for each prediction.

Actionable Recommendations:

To assist in decision-making, XMPro provides specific recommendations. For instance, it advises on expected low-fat content from an upcoming delivery and suggests blending with higher-fat milk to achieve the target percentage. Predictive alerts for potential pH imbalances are also provided, prompting checks for starter culture dosage and uniform distribution.

Operator Information:

The operator managing the process is identified, fostering accountability and traceability within the milk reception workflow.

In-Progress Batch Status:

The status bar at the top of the dashboard indicates that the milk reception process for the batch is in progress, providing a clear, high-level status update.

This Drilldown View of Milk Reception Monitoring Dashboard is a pivotal tool for ensuring the quality and efficiency of the milk reception process in dairy production, enabling proactive management and optimization of milk quality.”

Why XMPro iDTS for Dairy Processing Plant Operations?

XMPro’s Intelligent Digital Twin Suite (iDTS) delivers a suite of solutions specifically designed for the complex needs of managing dairy processing operations across multiple facilities. Here’s how XMPro iDTS revolutionizes dairy processing plant management:

Advanced Intelligent Digital Twin Modeling:

XMPro iDTS constructs detailed digital twins of dairy processing plants, offering a virtual model that reflects the intricate operations of facilities spread across different regions. This capability facilitates in-depth analysis and simulation of processing equipment performance, including pasteurizers, separators, and fermentation tanks, under various operational conditions. It’s instrumental for optimizing processes in plants with diverse environmental and production demands.

Advanced Sensor Data Integration & Transformation:

Integrating real-time data from sensors across all dairy processing equipment, XMPro iDTS captures critical metrics such as temperature, flow rates, and pressure levels. This extensive monitoring enables the identification and analysis of performance optimization opportunities throughout the dairy processing chain, ensuring uniform quality and efficiency.

Predictive Analytics for Performance Enhancement:

Leveraging cutting-edge predictive analytics, XMPro iDTS anticipates potential issues and optimizes operational settings for each piece of equipment. This foresight allows for proactive adjustments in processes like pasteurization and fermentation, maximizing product quality and throughput while minimizing waste and downtime.

Maintenance Scheduling Optimization:

By analyzing equipment performance data, XMPro iDTS streamlines maintenance schedules, adopting a predictive maintenance model over a reactive one. This approach is crucial for coordinating maintenance activities across multiple facilities, enhancing equipment longevity and reducing operational interruptions.

Real-Time Monitoring and Predictive Alerting:

Automated recommendations and alerts for equipment adjustments are generated based on real-time and predictive data analyses. This ensures that each piece of equipment, from homogenizers to cooling tanks, operates at optimal efficiency, significantly reducing the need for manual oversight.

Customizable and Interactive Dashboards:

XMPro iDTS provides customizable dashboards that offer real-time insights into the health and performance of equipment across all dairy processing plants. These dashboards are designed to be interactive, enabling detailed scrutiny of specific operational aspects and supporting centralized management decisions.

Scalability and Flexibility – Start Small, Scale Fast:

Designed to accommodate dairy operations of any scale, XMPro iDTS’s modular architecture allows for seamless integration and adaptability. This scalability ensures that dairy processing plants can efficiently manage operations as they expand or adapt to changing market demands.

Enhanced Safety & Operational Efficiency:

XMPro iDTS boosts operational safety by identifying potential hazards and inefficiencies in the processing line, ensuring that all equipment operates within safe and optimal parameters. This contributes to a safer working environment and more efficient production processes.

XMPro Blueprints – Quick Time to Value:

Offering quick time-to-value, XMPro Blueprints facilitate rapid deployment of digital twin solutions across dairy processing operations. These templates are built on industry best practices, ensuring that plants can quickly realize the benefits of digital transformation.

XMPro iDTS uniquely addresses the challenges of dairy processing plant operations by offering a holistic, predictive, and integrated management solution. Its advanced digital twin technology, combined with comprehensive data analytics and customizable dashboards, empowers dairy processors to achieve unparalleled operational efficiency, product quality, and safety across multiple facilities.